rubber process oil application

First, you should know what rubber process oil is and where it is used. The raw material for making rubber is rubber processing oil. But you should know that RPO has other uses. In the rest of this article, we will talk about the benefits of rubber process oil, rubber processing oil usage, and rubber process oil application, and we will answer the question of what is rubber processing oil used for.

This product is related to lubricants that contain less than 3% polycyclic aromatic compounds. Rubber process oil is used in the production of many rubber-related products. Rubber process oil is used to facilitate operations related to rubber manufacturing. The items used to make rubber are extrusion, kneading, molding, and other such things. In addition to the mentioned cases, rubber process oil application effectively improves rubber products’ physical properties. Also, rubber processing oil usage is used in natural and synthetic rubbers. According to these issues, rubber processing oil contains many aromatic hydrocarbons with a high affinity with rubber. In this article, we mention some uses of rubber processing oil. Including:

- Rubber process oil used in Automobile Tires

- Rubber process oil used in rubber shock absorbers

- Rubber process oil used in footwear

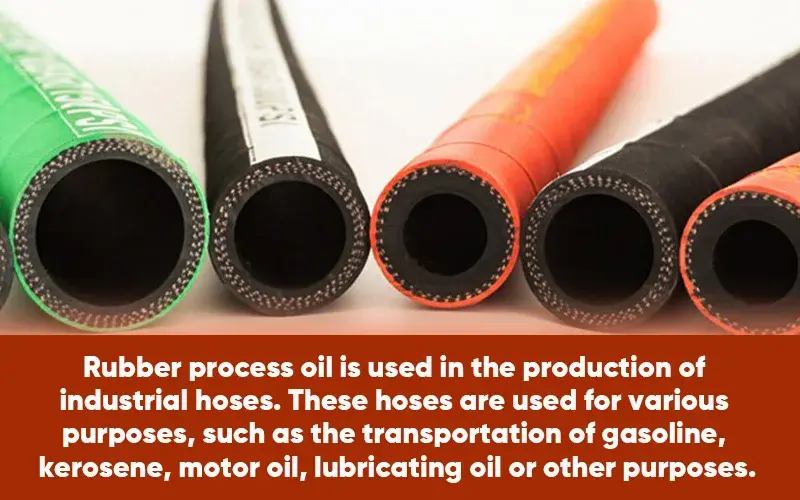

- Rubber process oil used in Industrial Hoses

- Rubber process oil used in wire and cable coverings

- Rubber process oil is used in flooring materials and carrier fluid

- Rubber process oil is used in the solvent in the manufacture of adhesives

- Rubber process oil used in sealants

- Rubber process oil used in polishes and carbon black

Stay with us in the rest of the article to check these items individually.

Rubber process oil used in automobile tires

Rubber process oil produces rubber compounds, especially car tire rubber, sizeable industrial machinery tires, and aromatic rubber. Due to its high viscosity compared to other oils, this oil produces hard, flexible tires such as car tires and marine impact tires. Rubber process oil is used in making tires for all types of cars, rubber rollers, trucks, and road construction machines; among the advantages of rubber process oil is a high ignition point and low volatility, which makes this oil used in producing all kinds of car tires. In the production of car tires, raw materials are first mixed in industrial mixers; at this stage, various rubber compounds are obtained from them. Considering that each tire has different physical and mechanical properties, it is necessary to consider other compounds for rubber production. In the production stage of car tires, rubber processing oil usage is the first word because it is very effective in the performance and resistance of car tires.

Rubber process oil used in rubber shock absorbers

Spring and rubber shock absorbers are two independent but essential components in cars. The function of the spring is to support the weight of the room on the suspension system, and the shock absorbers process absorbers absorb shocks caused by the car’s movement on the road. Shock absorbers are mechanical devices installed near each wheel to control the oscillations of the springs. One end of the shock absorbers is connected to the car chassis, and the other is connected to a moving part of the suspension system. In this situation, the movement of the spring increases and decreases the length of the shock absorbers. When the shock absorbers are compressed, the oil moves from the bigger holes of the valve, eventually changing its place quickly. If it reaches its expansion state, the return of the oil to its original position is possible through smaller channels. As a result of the oil return from the small ducts, the friction force of the oil increases, and the mechanical energy is converted into thermal energy, then the heat of the oil is spread in the space.

As you can see, shock absorbers have a vital role in cars. For this reason, rubber process oil application can help to improve its efficiency.

Rubber process oil used in footwear

As you have noticed, rubber processing oil usage is considered in various industries. RPO is used in automotive, manufacturing, construction, electronics, and other industries. For any product that requires high resistance, strength, and flexibility, rubber processing oil is used in those products. As mentioned above, RPO is used in car tires for industrial machinery, trucks, vehicles, and such. Also, rubber processing oil is used in building flooring and all kinds of durable and robust shoes.

Footwear is one of the essential items in today’s lifestyle. So, finding a suitable, durable, strong product for your use is imperative. RPO in footwear production can help the users of these imaginary products to have a comfortable feeling and not to worry about their loss. Rubber processing Oil is used in footwear raw materials and shows its performance after mixing with them.

Rubber process oil used in Industrial Hoses

Industrial Hoses are prepared and produced from rubber processing oil. Industrial Hoses are designed for suctioning and discharging a wide range of petroleum products, aircraft refueling, flexible reinforced oil hose, reinforced fuel pipes, and oil pipeline. Also, Industrial Hoses are used to transport gasoline, kerosene, motor oil and, lubricating oil, or other mineral oils in industrial and mining machinery, oil depots, terminals at an average temperature. An essential issue in this type of product is to pay attention to its strength, resistance, and flexibility.

Due to the great sensitivity of Industrial Hoses, their raw materials must have high strength, resistance to cold, and high heat. Therefore, during the production of Industrial Hoses, they take help from rubber process oil application. Due to its high strength, this oil is helpful for such purposes. Stay with us to answer questions like “What is rubber processing oil used for.”

Rubber process oil used in wire and cable coverings

Next, you should know that rubber processing oil is used in rubber formulation to produce rubber products. As we mentioned above, these products include rubber, rubber tape, hose, rubber bumper, shoes, wire and cable coverings, flooring materials, the solvent in producing glue and polish, and things like that.

The reason for using RPO in producing wire and cable coverings is its strength, flexibility, and pressure tolerance. So, rubber processing oil usage is one of the most critical raw materials used in all types of wire and cable coverings.

Rubber process oil is used in flooring materials and carrier fluid

The advantages of rubber processing oil usage, including unique color strength, good solubility, and thermal stability, have made this resistant material to be used in manufacturing flooring materials and a carrier fluid. RPO is mixed in the raw flooring materials, and after their consistency, you can use these materials to manufacture high-sensitivity products. Also, this material keeps the created unique color constant, and you will not have to worry about producing these products.

Rubber process oil is used as the solvent in the manufacture of adhesives

High viscosity furfural extract RPO has good elastomeric compatibility and aromatic process oil with low volatility. Due to its viscosity, which is considered to follow the standards, it is used to produce the solvent in the manufacture of adhesives. It is also interesting to know that its processing during milling, mixing, and extruding operations are very simple. These products generally have excellent solubility, good compatibility, and high viscosity. Also, the cost-effectiveness of rubber processing oil usage has caused it to be used in various industries.

Rubber process oil used in sealants

Rubber processing oil plays an essential role in various applications due to its excellent performance against air, resistance to aging, resistance to bending fatigue, and vibration damping. Among these applications, we can mention inner tire tubes, hoses, adhesives, and sealants. The tires made from rubber processing oil usage are suitable for industrial and consumer applications. These products must have good resistance, and depending on their type of activity; they must be flexible, waterproof, and able to seal. RPO is used in making the initial composition of Sealants.

Rubber process oil used in polishes and carbon black

The non-degradability of plastic bottles, plastic bags, tires, and battery waste has forced people and organizations to use non-environmental methods for disposing of polymer waste, including unsanitary landfilling and burning. These actions will cause many environmental and health effects. However, converting polymer waste into carbon black materials that can be used as pigments in shoe polish production is an effective and environmentally friendly disposal method. Resistance to fading and dust absorption and leather protection is one of the advantages of using rubber processing oil in products such as carbon black. In addition to high resistance, strength, and flexibility, the valorization of polymer waste is significantly reduced through the carbon black pigments in shoe polishes.

Various studies have been conducted on the valorization of polymer waste through conversion to wax or carbon black pigments for wax production. Different process variables affect wax quality, including temperature, carbon black particle size, black carbon source, and water-repellant type. The produced polish was applied to black leather, while physical properties such as wrinkle resistance, gloss, abrasion resistance, fading resistance, and dust absorption resistance were evaluated. Rubber processing and oil usage are very effective in producing products’ quality and resistance.

Summary of the article What is rubber processing Oil used for?

RPOs are prepared from aromatic furfural extract from selected refineries. They are compounded to meet stringent specifications for manufacturing tires, latexes, tubes, rubber compounds, engine belts, hoses, battery housings, containers, and more. Many hydrocarbon rings are linked, indicating a range of degrees in them. Their exceptional color stability, solubility, and thermal stability make them useful for molded products, slippers, LPG pipes, floor tiles, etc.

Our rubber processing oils cover a wide range of applications. You should also know that these oils are environmentally safe. Rubber processing oil usage is available in different grades and exceptional quality for use in producing natural and synthetic rubber products. Rubber processing oil is used when mixing rubber compounds. This material helps improve the compound’s filler dispersion and flow properties during further processing. Based on the physical arrangement of carbon atoms, rubber processing oil usage can be divided into several categories.