Proper lubrication is critical to the smooth operation and longevity of machinery and equipment. And choosing the right base oil for your lubricant is a crucial step in the lubrication process. With so many different types of base oils available, it can be overwhelming to determine the right one for your specific needs. In this article, we will explore the different types of base oils, their characteristics, and the factors to consider when selecting the right one for your lubricant needs. We will also discuss the importance of balancing performance, cost, and environmental impact in base oil selection, choosing the right additives, testing and certifications, maintenance and storage, innovations and advancements, and successful case studies. By the end of this article, you will have a better understanding of how to choose the right base oil for your lubricant needs.

Understanding Base Oils and Their Importance in Lubrication

Base oils are the foundation of any lubricant, providing lubrication and protection to machinery and equipment. They are typically derived from crude oil and are refined to create high-quality oils that meet specific performance requirements. The quality of the base oil has a significant impact on the lubricant’s overall performance, including its ability to reduce friction, prevent wear, and resist oxidation.

Different Types of Base Oils and Their Characteristics

There are various types of base oils, including mineral oils, synthetic oils, and vegetable oils. Mineral oils are the most commonly used and are derived from crude oil. Synthetic oils, on the other hand, are man-made and offer improved performance characteristics such as better temperature resistance, improved wear protection, and longer life. Vegetable oils are derived from natural sources and are used primarily in environmentally friendly lubricants.

Factors to Consider When Choosing a Base Oil for Your Lubricant

When choosing a base oil for your lubricant, there are several factors to consider, including operating conditions, performance requirements, and equipment compatibility. Operating conditions such as temperature, load, and speed can have a significant impact on the performance of the lubricant. Performance requirements such as viscosity, wear protection, and oxidation resistance should also be considered when selecting a base oil.

virgin and recycled base oil sn 150

Matching Viscosity Requirements with Base Oil Properties

Viscosity is an essential property of base oils, and it determines the lubricant’s ability to reduce friction and prevent wear. When selecting a base oil, it is crucial to match the viscosity requirements of the application with the properties of the base oil. The viscosity of the base oil can be modified by adding viscosity improvers, but this can also impact the lubricant’s performance in extreme temperatures.

Balancing Performance, Cost, and Environmental Impact in Base Oil Selection

Selecting the right base oil involves balancing performance requirements with cost and environmental impact. High-performance synthetic oils may offer improved performance, but they can also be more expensive than mineral oils. Vegetable-based oils are an environmentally friendly alternative, but they may not offer the same level of performance as mineral or synthetic oils.

Choosing the Right Additives for Your Base Oil and Lubricant

Additives are often added to base oils to improve their performance characteristics. Additives can improve the lubricant’s ability to reduce friction, prevent wear, and resist oxidation. When selecting additives, it is crucial to consider the application and performance requirements of the lubricant.

Testing and Certifications for Base Oil and Lubricant Quality

Testing and certifications are essential for ensuring the quality and performance of base oils and lubricants. Various organizations offer certifications and testing services to verify the performance and quality of base oils and lubricants.

Maintenance and Storage of Base Oil and Lubricants

Proper maintenance and storage of base oils and lubricants are essential for ensuring their performance and longevity. Lubricants should be stored in a clean and dry environment to prevent contamination, and they should be properly labeled and tracked to ensure proper use and disposal.

Innovations and Advancements in Base Oil Technology

Base oil technology is continually advancing, with new synthetic oils and renewable options being developed. These advancements offer improved performance and environmental benefits, and it is essential to stay up to date on the latest developments in base oil technology.

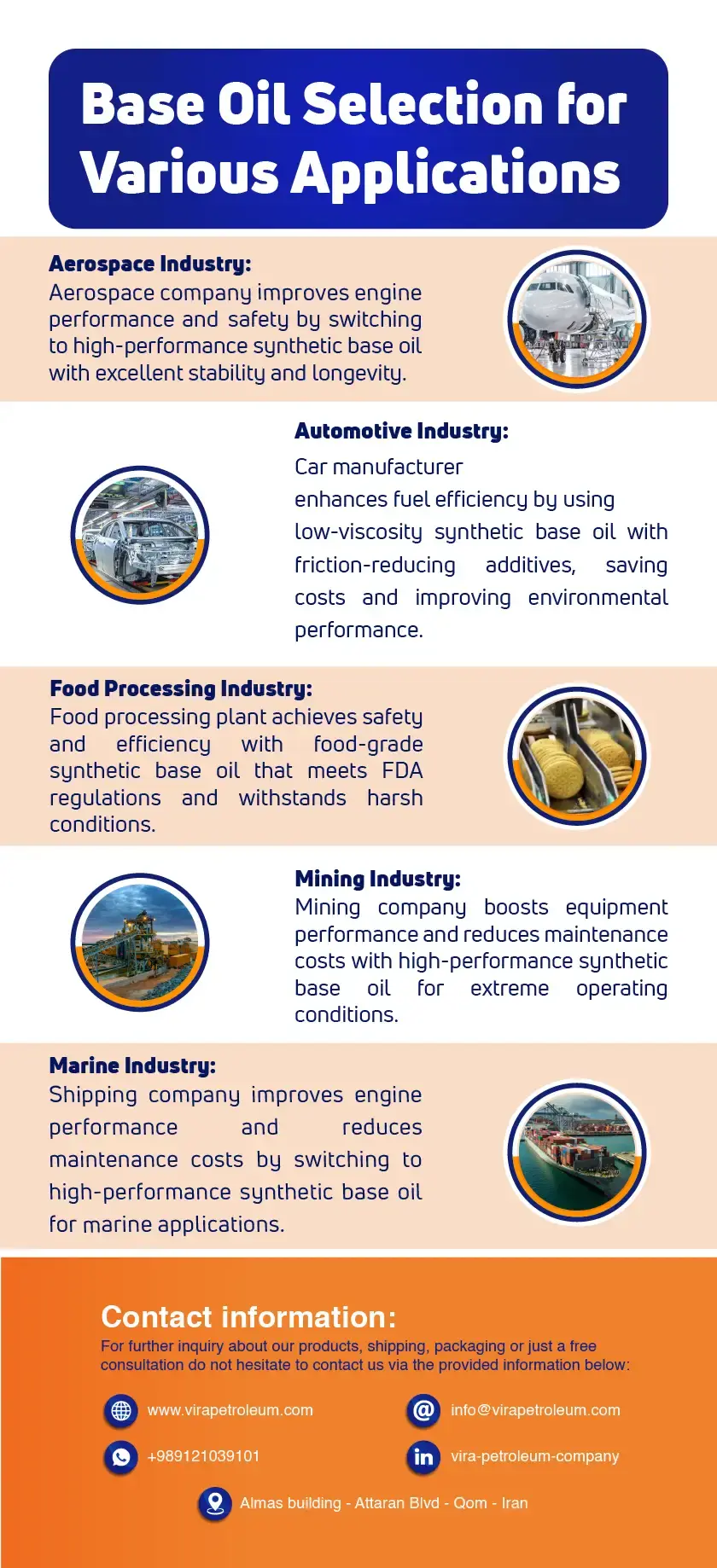

Case Studies: Successful Base Oil Selection for Various Applications

Aerospace Industry:

In the aerospace industry, lubrication is critical for ensuring the safe and reliable operation of aircraft engines. A major aerospace company was experiencing issues with their engine lubrication system, resulting in increased wear and tear on critical engine components. After evaluating different base oil options, the company switched to a high-performance synthetic base oil with excellent thermal and oxidative stability. The new base oil helped improve engine performance and longevity, leading to reduced maintenance costs and improved safety.

Automotive Industry:

A leading car manufacturer was looking to improve the fuel efficiency of their vehicles by reducing friction in engine components. They tested various base oils with different viscosity and additive packages before settling on low-viscosity synthetic base oil with advanced friction-reducing additives. The new base oil helped improve fuel economy by reducing frictional losses in the engine, resulting in cost savings for the company and improved the environmental performance of their vehicles.

Food Processing Industry:

In the food processing industry, lubrication is essential for maintaining the integrity and safety of food products. A large food processing plant was looking for a base oil that met strict FDA regulations and could withstand high temperatures and aggressive chemical cleaning agents. After evaluating different options, the plant switched to a food-grade synthetic base oil that met all regulatory requirements and had superior thermal and chemical stability. The new base oil helped reduce downtime and maintenance costs, while also ensuring the safety and quality of food products.

Mining Industry:

The mining industry relies heavily on large machinery and equipment, and proper lubrication is critical for maximizing their performance and minimizing downtime. A mining company was experiencing issues with premature equipment failure and high maintenance costs due to the harsh operating conditions in their mine. After conducting extensive testing, they switched to a high-performance synthetic base oil with exceptional wear protection and thermal stability. The new base oil helped extend equipment life, reduce maintenance costs, and increase productivity.

Marine Industry:

The marine industry requires lubricants that can withstand the harsh conditions of seawater, high temperatures, and heavy loads. A shipping company was experiencing issues with their engine lubrication system, leading to increased wear and tear on engine components and frequent breakdowns. After evaluating different base oil options, they switched to a high-performance synthetic base oil with excellent water resistance and wear protection properties. The new base oil helped improve engine performance, reduce maintenance costs, and ensure the safe and reliable operation of their ships.

Conclusion:

In conclusion, choosing the right base oil is crucial for ensuring optimal lubricant performance and longevity. It is important to consider factors such as viscosity, additives, cost, environmental impact, and the specific application when selecting a base oil. Different types of base oils have unique characteristics and properties, so it is important to understand their differences and how they affect lubricant performance. Testing and certifications can also help ensure the quality of base oils and lubricants. Finally, advancements in base oil technology and successful case studies demonstrate the importance of staying informed and up-to-date on developments in the industry. By following these guidelines and considerations, individuals and businesses can make informed decisions and select the right base oil for their lubricant needs.

FAQ:

The factors to consider include viscosity requirements, operating temperature, compatibility with additives, environmental impact, and cost.

You can match viscosity requirements with base oil properties by understanding the kinematic viscosity, viscosity index, and shear stability of the base oil.

Common additives used in lubricants include detergents, dispersants, anti-wear agents, and friction modifiers. You should choose additives based on the specific performance requirements of your lubricant and the compatibility with your base oil.

Testing and certifications help ensure that your base oil and lubricant meet industry standards and performance requirements. This can help prevent equipment failure, reduce downtime, and extend equipment life.

Advancements in base oil technology have led to the development of synthetic and bio-based oils, which offer improved performance, durability, and environmental sustainability. When choosing a base oil, you should consider these advancements and whether they align with your performance and sustainability goals.