Base oils Additives are among the things that will change the characteristics of the base oil, and in this situation, we can use compounds obtained in different industries. Base oils are the main components of lubricants. Base oils are combined with additives and create new properties. Base oils are developed with additives considered by the research team and create new functional compounds. Additives are chemicals designed to enhance the properties of base oils.

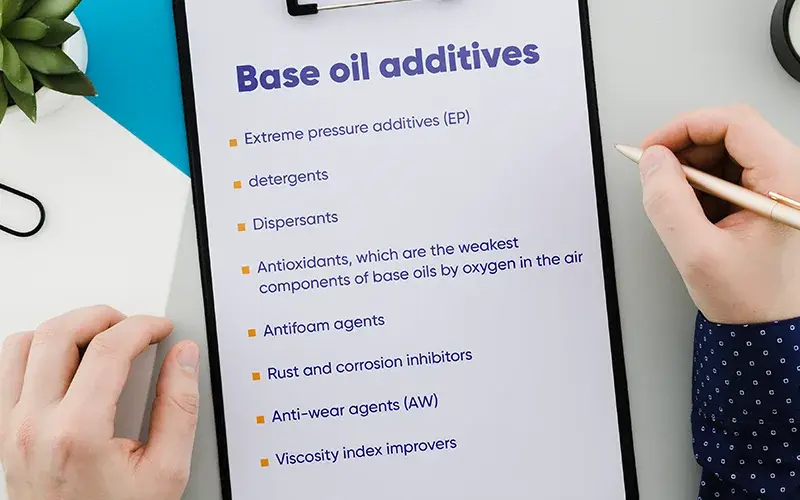

Some additives are considered to improve base oils, which can change their properties according to the industry’s needs. Among the additives that will enhance Base oils, we can mention the following:

- Extreme pressure additives (EP)

- detergents

- Dispersants

- Antioxidants, which are the weakest components of base oils by oxygen in the air

- Antifoam agents

- Rust and corrosion inhibitors

- Anti-wear agents (AW)

- Viscosity index improvers

Here it is necessary to know that the additives intended for base oils will not harm your engines. These additives are designed to help improve the performance of base oils by creating new features. It is interesting to know that five additives, including Corrosion Inhibitors, Viscosity Index Improvers, Antioxidants, Detergents, and Additional additives, are among the most common additives for base oils. Base oil and additives play an essential role in improving the engine process.

Base oil and additives

The basis of base oil is to be present in more than 50% of the final product. Additives are considered for base oils when they provide high stability and improve viscosity-temperature behavior and unique properties. Modern lubricants consist of different ingredients and will improve base oil conditions. As you know, the oil that is considered as a base for lubricant and after adding additives to it, the final petroleum is obtained is called Base oil. Base oil is the most critical component of lubricants in terms of volume, and it should make up 95% of a lubricant by weight. It has also been seen that some other lubricants, such as greases, metalworking fluids, or industrial gear oil, contain 30% additives. Because crude oil contains various compounds such as naphthenic and aromatic, paraffinic hydrocarbons, and sulfur compounds, Base Oil is also formed from these compounds. Some components in crude oil increase the quality, but others have undesirable properties. The two categories of hydrocarbons and non-hydrocarbons are components of crude oil and base oil. Base oil and additives in the obtained compounds will create unique characteristics for industrial applications.

Base oils overview

More than Base Oil is required in most industrial applications to perform the wide range of tasks that an application oil must perform. Combining additives with base oils is necessary to develop new, widely used products to increase the quality of work and create unique features to achieve the intended studies. This issue causes oil alloying, and by creating new properties in base oils, they will make new and widely used products.

- Ester is a natural and synthetic liquid obtained from alcohol or acid.

- Mineral oil raffinate is obtained by vacuum distillation of crude oil.

- Polyisobutylene (PIB) and Poly-α-Olefin (PAO), obtained from synthetic base oil with a paraffinic base structure.

- Silicone oil is a synthetic liquid or, in other words, polydimethylsiloxane PDMS.

- Bone oil, a lubricating oil obtained from bone, is considered for precision mechanical drives.

- Hydrocracking oil is created through the thermal treatment of mineral oil with molecular structure.

- Glycols are polyhydric alcohol that is synthetically obtained from coal or petroleum.

- Per fluorinated hydrocarbons is a synthetic oil based on perfluorinated polyether oils.

- Alkylbenzene is a synthetic oil based on aromatic hydrocarbons.

Overview of additives

Depending on the need and type of use of oils in different industries, additive components are combined to create a new package with new features. The active ingredients and additive packages are vigorously mixed with the base oil at temperatures up to 40°C and sometimes 60°C to combine with the oil. In engine oil, the additive content can be considered 20%, but this amount is reduced to 1% for hydraulic oil.

Some types of additives are as follows:

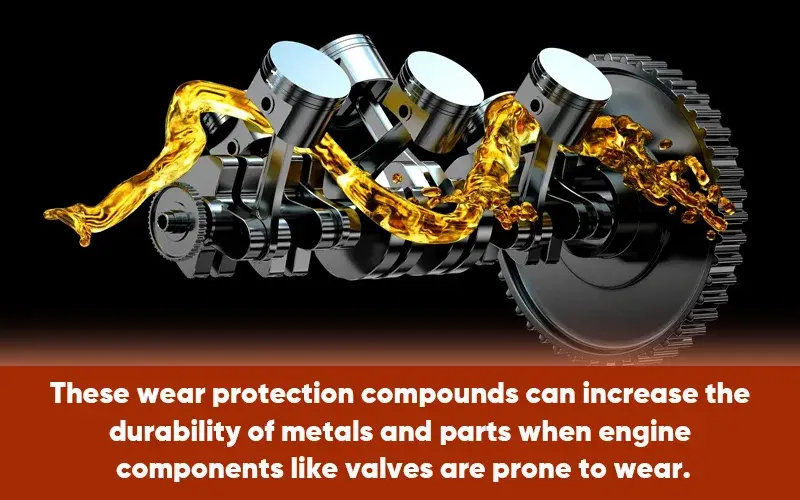

Wear protection additives

This additive, combined with the base oil, prevents direct friction with the metal and ultimately prevents wear. They also use acids, esters, fats, and sulfur-containing compounds as anti-wear materials. When engine components such as valves are subject to wear, these anti-wear compounds can help the durability of metals and parts.

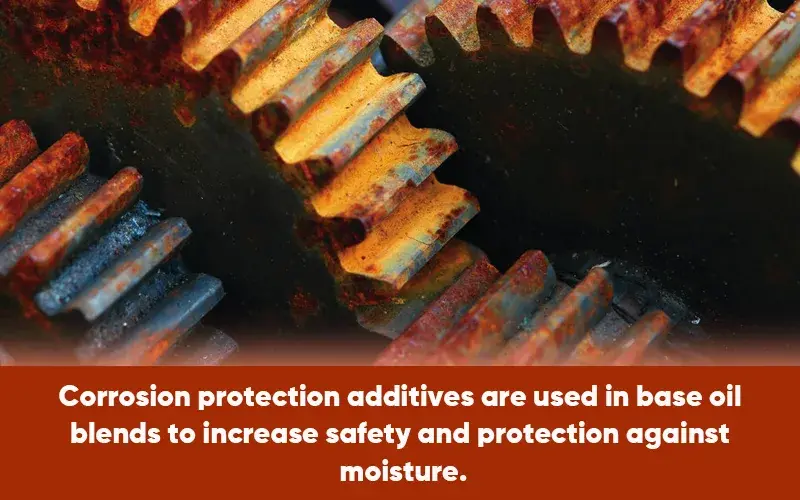

Corrosion protection additives

These additives protect metal surfaces against the attacks of moisture and acids or alkalis; This is why this additive is used in base oil compositions to create protection against water, acids, or alkalis in them. It is essential to pay attention to Base oils and Additives in the considered pieces. In general, oils are resistant to corrosion and aging, but when water enters the oil, rust or corrosion also occurs. Additives are used in base oil blends to increase safety and protection against moisture and other things.

VI improvers:

In some Base oils Additive types, viscosity’s dependence on temperature is optimized. Some additives are dispersed in oils, and when the oil temperature rises, it improves the VI improvers by dissolving the polymers. These materials are primarily used in multigrade oils.

virgin and recycled base oil sn 150

Friction coefficient modifier:

Base oil and additives in some types will cause the precise adjustment of the friction coefficient. Additives are added to the base oil, and in the fast movement of industrial machines, friction will be taken into account, and possible damage to the device will be prevented.

Oxidation protection additives:

additives combined with base oil prevent oxidation or slow its process. Some compounds in the oil are exposed to oxidation due to engine heat and contact with air. To prevent oxidation, additives are added to base oils. These additives increase the durability and useful life of oils.

Detergents and dispersants:

It has been seen in some Base oils and Additives that assume unique features such as removing dirt or carrying dirt. In fact, with new combinations of additives and base oils, many soot particles and substances caused by combustion will be lost. Cleaning and suspending additives are added to most lubricating oils to take the necessary measures to remove deposits. The higher the number of additives, the more cleaning power the oil has, and it will turn black sooner, and the lower the number of additives, the later the oil will turn black. The blackening of the grease later causes deposits to settle in the engines, which can be harmful.

Swell Agents:

Some types of Base oils Additives seal the oils and prevent the swelling of metals. Additives are added to the base oil and protect against swelling of engines and engine-related parts.

Anti-foam additive:

Base oil and additives will cause essential and unique oil characteristics. Anti-foam additive is added to base oils to prevent oil foaming and damage caused by oil foaming. This type of additive helps to improve foaming properties. The high movement speed and the air introduced into the oils cause foaming when working with industrial machines.

Mixing different oils

You must have heard about mixing different oils. You should know that it is wrong to mix other oils, even if the base oil is the same. You should keep the same types of oil even if they have the same viscosity. For example, you cannot mix engine oil with hydraulic oil. Also, mixing compressor oil with gear oil is not allowed. You can only use the combination of additives with base oils, but you need to know that you need complete information about additives and base oil to be allowed to use their variety. In industrial applications, many things could be improved in this field. Mixing or contaminating the base oil with an unknown lubricant will cause many problems in various industries. Oils with the same base oil, similar viscosity, and specific density can be mixed. Of course, you should consider that the compatibility of mixed oils depends on the additives.

Finally, you should know that miscibility does not mean the compatibility of mixed oils. Hence, the critical issue is that mixing oils or additives will happen when these materials are compatible.

Miscibility

Miscibility is a chemical reaction. Miscibility occurs when two substances are thoroughly mixed together. For example, two types of oil with additives become miscible when they can be completely dissolved or mixed. Miscibility may be considered, but two substances are incompatible; This is also true for base oil and additives. Of course, it is essential to note that compatibility is more critical than miscibility, and you should use the two sparingly.

Compatibility

One of the most critical issues related to the combination of oils or base oil and additives is their compatibility. When mixing, the oils retain their properties, which makes compatibility in some mixtures not created. As we mentioned above, according to the properties of the oil or additives, we can determine miscibility, but it is challenging to assess their compatibility. It must be considered that additives are placed next to base oils with the same properties to create compatibility after mixing. If compatibility is not established when mixing oils or oil mixtures with additives, the following problems arise:

- Changing the wear protection behavior

- More contamination of the mixture due to dissolved sediments

- Increased formation of sediments due to high reactions

- Increased formation of surface foam

- Increased risk of cavitation

- Affected by demulsifying or emulsifying properties

- Changing friction characteristics

- Improper filterability or reduced helpful life of the filter

- Seal wear

- Changing behavior toward water

5 Amazing Facts About Potential Applications of Base Oil

Try to check the following in situations where it is necessary to mix ingredients:

First, you should know that the two combined oils must have the same base oil, and checking the viscosity and density in this situation is essential. If the base oil is different, avoid mixing them as much as possible.

As we said in the previous step, checking the viscosity is very important. So, if the base oils were similar, compare the viscosity. In fact, for oils with different viscosities, the viscosity does not change linearly. Finally, decide whether the viscosity of the two oils is tolerable.

The most challenging part of the review is additives, which require specialized knowledge. Base oils Additives need to compare data and information that only the information provided by the manufacturers is not enough. It is necessary to perform a compatibility test at this stage so that if the combined materials are incompatible, they should be avoided in large quantities.

Never mix these oils:

- Detergent and non-detergent oils

- Glycol-based synthetic oils with other synthetic oils

- Zinc-free and zinc-containing hydraulic and circulation oils

How to avoid mixing

Better to reduce the risk of unwanted mixing during your daily use of oils. It would be best if you considered some things in the storage place of oils and additives to minimize the possibility of unwanted mixing of oils and the occurrence of problems. Paying attention to Base oils Additives will reduce the likelihood of the issues.

It is better to put cans containing oil in different colors and separate places so that they are not used interchangeably and are not mixed. For each oil, a different lubricant and additives should be considered separately. Only use containers of other oils that are finished for new oils; the same small amount left in the oil can likely cause incompatibility. Consider separate cards for different oils and write specific information on them. It is possible that the information provided by the manufacturer needs to be completed, so check them before combining oils or additives.

Additional tips

It is better to consider the risk of mixing and many other sources of error during storing and handling lubricants and additives so that you do not have problems and subsequent issues. There is a lot of information about mixing oils and oils with additives, so be sure to use an expert’s opinion in these situations. It is essential to pay attention to Base oils Additives because there is a possibility that the combined materials are not compatible with each other. Try to master the information provided on the oil packages to reduce the likelihood of error. Also, for Base oil and additives, keep in mind that oil additives should also be checked separately.