The pressing concerns surrounding climate change and the need for sustainable energy sources have spurred interest in alternative fuels. Diesel fuel, known for its efficiency, is primarily derived from non-renewable crude oil. However, an innovative solution exists that tackles both energy and waste management challenges simultaneously: converting waste oil into diesel fuel. This comprehensive article explores the process of making diesel from waste oil, its environmental advantages, and its potential as a sustainable energy solution.

Order : recycled base oil

Understanding Waste Oil:

Waste oil refers to discarded petroleum-based or synthetic oil used in various applications, including vehicle engines, industrial machinery, and cooking. Inadequate disposal of waste oil can result in environmental pollution, leading to soil and water contamination.

The Conversion Process:

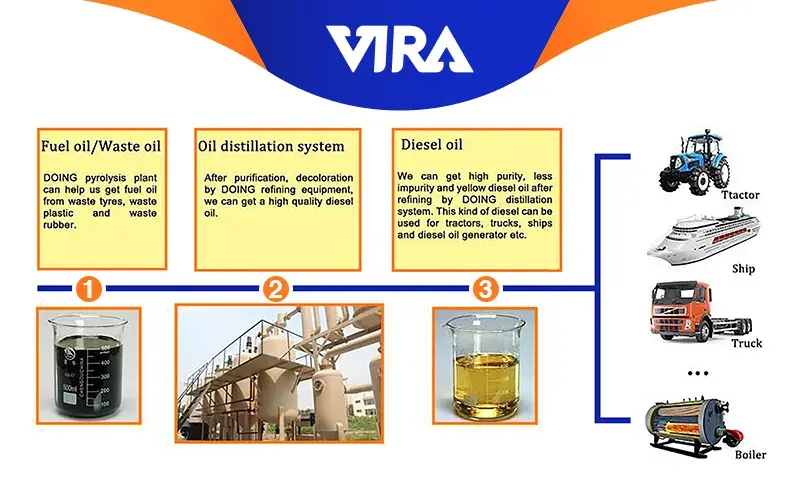

Converting waste oil into diesel fuel involves a refining technique known as pyrolysis, which entails the thermal decomposition of organic materials in the absence of oxygen. The following steps outline the process:

Read more : 11 Significant Benefits of Reusing and Recycling Waste Oil

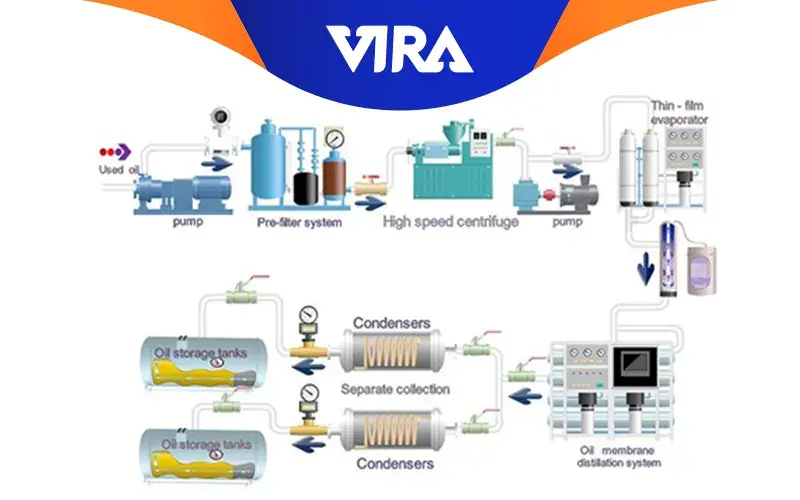

Collection and Filtering:

Waste oil is collected from different sources and subjected to thorough filtration to eliminate impurities like solid particles, water, and contaminants.

Pre-Treatment:

Filtered waste oil undergoes pre-treatment to remove any remaining water and solids, ensuring optimal performance and efficiency during the refining process.

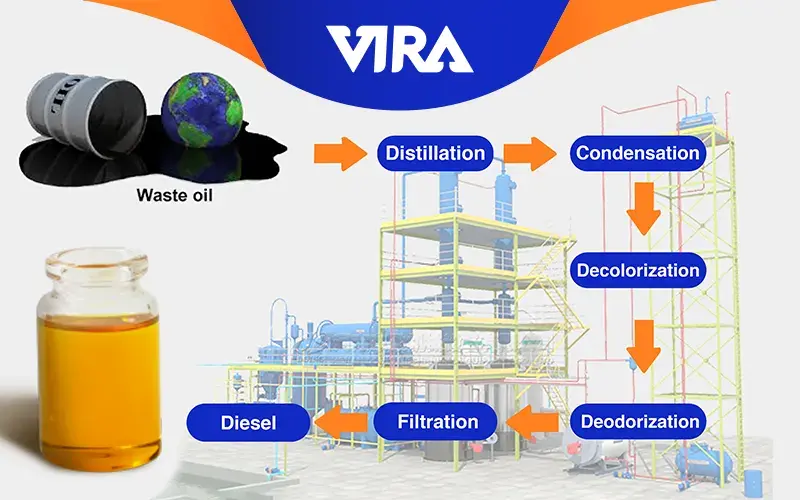

Pyrolysis

The pre-treated waste oil is subjected to pyrolysis, involving heating it to a specific temperature range to break down the hydrocarbon chains. This process yields a mixture of gases, liquids, and solids.

Fractional Distillation

The products of pyrolysis are further processed using fractional distillation, a separation technique that segregates different components based on their boiling points. This process yields diesel-like fractions as the desired output.

Post-Treatment

The diesel-like fractions undergo additional refining processes, such as hydrogenation and desulfurization, to enhance fuel quality and eliminate impurities. This ensures the final product meets the required specifications.

Conversion Process of Waste Oil to Diesel Fuel

| Step | Description |

| Collection and Filtering | Waste oil is collected from various sources such as vehicles, industrial machinery, and cooking oils. It undergoes filtration to remove impurities like solid particles, water, and contaminants. |

| Pre-Treatment | The filtered waste oil undergoes pre-treatment to remove any remaining water and solids, ensuring better performance and efficiency during the refining process. |

| Pyrolysis | The pre-treated waste oil is heated through pyrolysis, a process that breaks down the hydrocarbon chains in the oil. This results in a mixture of gases, liquids, and solids. |

| Fractional Distillation | The products of pyrolysis are subjected to fractional distillation, where different components are separated based on their boiling points. Diesel-like fractions are obtained as the desired output. |

| Post-Treatment | The diesel-like fractions undergo additional refining processes, such as hydrogenation and desulfurization, to improve fuel quality and remove impurities, ensuring compliance with required specifications. |

Environmental Benefits

Converting waste oil into diesel fuel offers several environmental benefits:

Read more : Various Types of Waste Oil

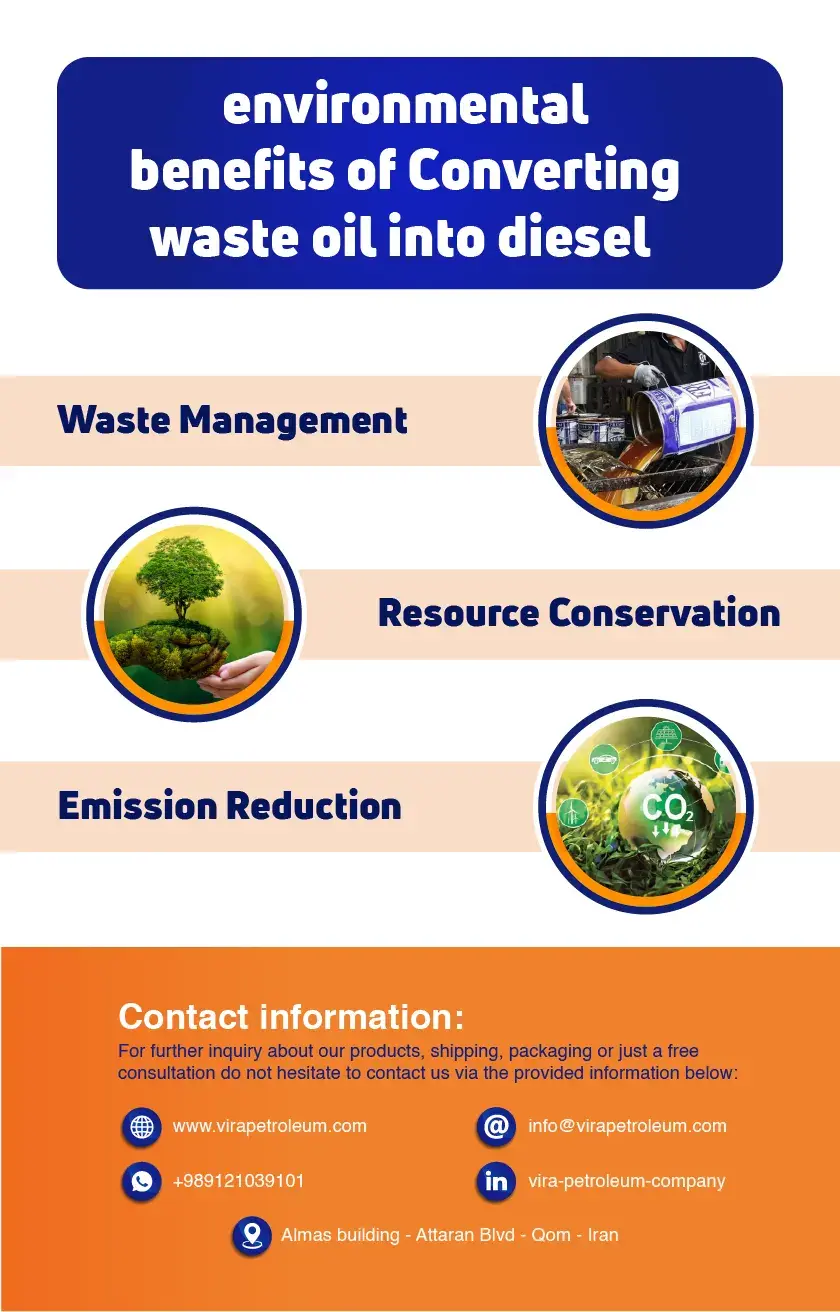

Waste Management:

Utilizing waste oil as a feedstock for diesel production significantly reduces improper disposal and incineration, effectively mitigating associated environmental hazards.

Resource Conservation:

The conversion process reduces dependence on non-renewable crude oil, thereby extending its lifespan and conserving valuable natural resources. Additionally, this process reduces the carbon footprint associated with traditional diesel production.

Emission Reduction:

Diesel fuel derived from waste oil generally exhibits lower sulfur content than conventional diesel, resulting in reduced sulfur dioxide emissions. Furthermore, the combustion of waste oil-derived diesel produces fewer particulate matter emissions, contributing to improved air quality.

Challenges and Considerations:

While the conversion of waste oil into diesel fuel shows immense potential, it’s crucial to consider the following challenges:

Quality Control:

Maintaining consistent fuel quality and meeting regulatory standards during the conversion process can be challenging. Stringent quality control measures and regular testing are essential to ensure optimal fuel performance and prevent adverse effects on engines and equipment.

Economic Viability:

The economic feasibility of waste oil-to-diesel conversion depends on various factors, including waste oil collection costs, conversion process efficiency, and market demand for the final product.

Sustainability of Feedstock:

The availability and sustainability of waste oil as a feedstock may vary geographically and over time. Establishing a stable and reliable supply chain for waste oil is crucial for the long-term viability of this approach.

Advancing Waste Oil-to-Diesel Conversion: Key Steps for Widespread Adoption

To promote widespread adoption of waste oil-to-diesel conversion, several key steps can be taken:

Establish a Sustainable Supply Chain: It is essential to develop partnerships with industries and organizations to ensure a stable and reliable supply of waste oil. This can be achieved through effective waste oil collection systems, collaborations with recycling centers, and public awareness campaigns encouraging proper waste oil disposal.

Enhance Conversion Efficiency:

Continued research and development efforts should focus on optimizing the conversion process and refining techniques. This includes exploring advanced technologies and catalysts that can improve the efficiency and yield of diesel production from waste oil.

Invest in Quality Control:

Stringent quality control measures must be implemented to ensure consistent fuel quality and adherence to regulatory standards. Regular testing and monitoring should be carried out to verify the performance and compatibility of waste oil-derived diesel with engines and equipment.

Economic Viability and Market Demand:

Economic feasibility is a crucial aspect of waste oil conversion. It is important to assess the cost-effectiveness of the process, taking into account waste oil collection costs, refining expenses, and market demand for the final product. Government incentives, grants, and tax benefits can encourage investment in waste oil-to-diesel conversion facilities.

Collaboration and Policy Support:

Governments, environmental organizations, and businesses should collaborate to create supportive policies and incentives. These can include regulatory frameworks that promote the adoption of sustainable energy solutions, tax incentives for waste oil recycling, and grants for research and development in waste oil conversion technologies.

By implementing these strategies and addressing the challenges associated with waste oil conversion, the widespread adoption of this innovative process can be facilitated. This will contribute to a more sustainable energy system, reduce environmental impact, and promote the circular economy.

Conclusion:

In conclusion, making diesel from waste oil provides a sustainable and environmentally friendly alternative to traditional diesel production. By addressing waste management challenges, reducing reliance on non-renewable resources, and minimizing emissions, this process contributes to a greener and more sustainable future. With further research, investment, and support, waste oil conversion has the potential to play a significant role in the transition towards a cleaner and more efficient energy system.